Transit Time Flow Meter

The acoustic method of discharge measurement is based on the fact that the propagation velocity of an acoustic wave and the flow velocity are summed vectorially.

summed vectorially.

It follows that an acoustic pulse set upstream travels at a lower absolute speed than an acoustic pulse send downstream. By measuring the times of traverse of pulses sent in the two directions, the average axial velocity of the fluid crossing the path of the pulses is determined.

In a flow meter, the transducer converts a high voltage electrical pulse at a given frequency into mechanical vibration. This creates a sound wave that is transmitted through the water in the desired direction according to the characteristic radiation pattern of the transducer. All piezo-ceramics have at least one series resonant frequency at which they vibrate most easily. This is dependent on the ceramic material, shape and dimensions. Attenuation of sound in water increases with frequency. Because there is less attenuation of lower frequency signals, lower frequencies must be used to achieve longer path lengths.

In recent years the acoustic flow measurement has established itself as the standard method for measurements on many hydrological stations. With this almost contact free technology data can be recorded continuously and it provides twenty-four-seven monitoring.

This systems used in Rivers, Hydro Power, Channels, Water Supply, Wastewater and Industries.

Features

Datalogger

- Acoustic Paths:1 – 8, length 1 – 30 m

- Frequency: 200 kHz

- Accuracy: ± 2% (typical)

- Display: 4 lines, 20 characters

- Data logger: Internal, Sampling Interval

- Communication: RS-232, MODBUS, Ethernet, USB

- Inputs: Max. 8 x 4-20 mA

- Outputs: Max. 4 x 4-20 mA2 x Relay, 2 x Puls

- Power Supply: 85-264 VAC (50-60 Hz)or 12 VDC

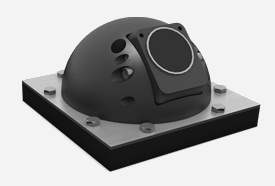

Transducer

- Frequency: 200 kHz

- Beam Width: 8° or 18° (-3dB)

- Dimensions: Ø 31,8 mm, Height 50 mm or Ø 70 mm, Height 40 mm